Description

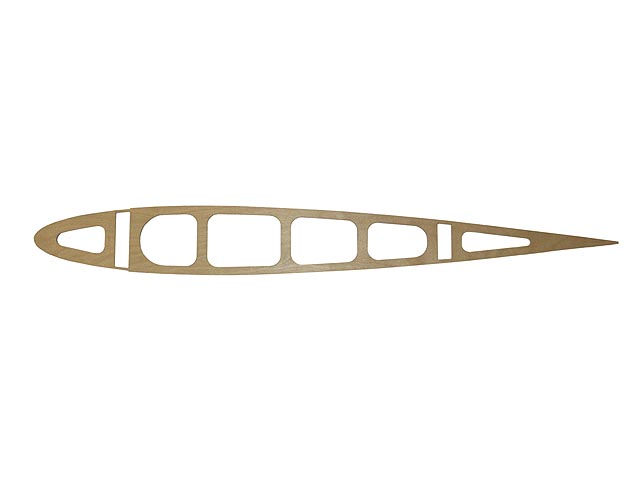

These high-quality formed leading edges are made of two layers of .032 inch birch aircraft plywood, which are laminated together onto a form. Vacuum forming is used to provide an incredibly strong, consistent, and accurate product. Plywood leading edges have many advantages over the traditional aluminum method. Unlike aluminum, it is easy to make a structural bond between the leading edges and the spar and ribs using epoxy. This also helps to increase the torsional strength and stiffness of the wing by forming a “D-box” structure. Hardware is not needed to hold ply leading edges to the spar, so there are no worries about nails working loose and adding weight. Laminated plywood is very sturdy and ding-resistant, and if you do sustain hangar rash to these leading edges, you can generally effect a repair like you would any other wooden component. They are also easy to fair in smoothly with the rest of the structure, which helps to make for a smooth covering job. You may cut holes in these (such as for pitot tubes or inspection plates) as needed. Priced per set of five – upper and lower right and left, plus the upper center section.

NOTE: Custom sizes are available to fit other aircraft. Please call or email for information.

SHIPPING NOTE: Due to the size of this item, it must be shipped via truck freight.

Reviews

There are no reviews yet.