Aircraft Products

Flying Wires – Brought to you by Bruntons Aero Products

Bruntons Aero Products Ltd. has been developing the art of flying wire manufacturing since 1909, six years after the Wright Brothers. Their quality is known and respected throughout the aviation industry worldwide. Steen Aero Lab is proud to be the North American distributor for Bruntons Aero Products. (More about Bruntons)

Streamline Wires and Tie Rods are used for internal or external bracing on aircraft (wings, tail surfaces, undercarriages, floats etc.)… wherever a load in tension must be carried.

Streamline Wire and Tie Rod Features

Bruntons works hard to ensure that their products represent the high level of quality that is expected for flight-critical aerospace applications:

Bruntons works hard to ensure that their products represent the high level of quality that is expected for flight-critical aerospace applications:

- All wires (tie rods) are made from 316 Stainless Steel, and all terminal hardware is made from 6S80 Stainless Steel, for the ultimate in corrosion resistance.

- All wires and rods are produced from ground bar, which is either cold drawn (tie rods) or cold rolled (streamline wires) to produce the required strength, toughness and ductility.

- Threads on the wires are rolled, which is stronger than traditional cut threads.

- Wires are available in either a high-polish mirrored finish (AN Specification) or satin finish.

- Wires are available in BSF or metric thread, for absolute authenticity for that antique restoration.

- You can order wires with combinations of streamline and round cross-sections.

- All wires are tested to 100% of their designed load before leaving the factory.

- Wires ordered with terminals are supplied assembled.

- Every order includes a quality certification.

- All wires are specially produced for each customer. You will get exactly what you need.

Special Streamline Wires

Streamline wires can be supplied with non-standard length round portions, or with round center sections between two streamlined sections. When non-standard streamline wires are required, orders should be accompanied by drawings and/or detailed specifications where possible.

Ordering

Every set of wires or tie rods is custom-made to your requirements. To order, the following information is essential:

- Type: Streamline Wire of Round Tie Rod

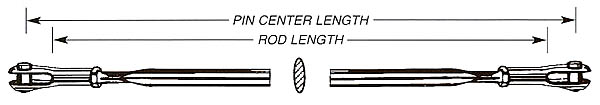

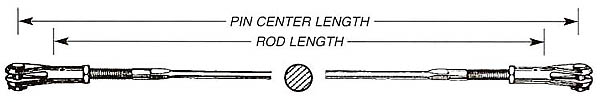

- Length: Lengths should be quoted in either inches or millimeters. Please specify whether the length given is Rod Length (R.L.) or Pin Center Length (P.C.L.)

- Terminals: Please specify if terminals are required with your streamline Wires / Tie Rods. If terminals are required, they will be selectively assembled at the factory to ensure a perfect fit. All fitted terminals will be supplied complete with clevis pins, split pins and locknuts. All terminals are manufactured from stainless steel.

Please take time to double-check all measurements. Due to the fact that every wire set is custom-made, unfortunately we are unable to provide refunds for wires produced according to incorrect measurements provided by the customer. If in doubt, please call Steen for assistance in determining the proper way to measure for your wires.

(We do offer a complete wire set for the Skybolt which will fit properly on a plane which has been built to the plans. Contact us for more details.)

| TIE ROD NOTES |

|

|

||||||

| AN NUMBER | Size & Thread |

Diameter (Inches) |

Thread Length (Inches) | K | Min. Strength (lbs.) |

|

| RH | LH | |||||

| AN671AC- | 6-40 | .138 | 1-3/4 | 1-1/4 | 1-1/4 | 1,200 |

| AN673AC- | 10-32 | .190 | 1-7/8 | 1-3/8 | 1-1/2 | 2,400 |

| AN674AC- | 1/4-28 | .250 | 2-1/8 | 1-5/8 | 1-7/8 | 4,200 |

| AN675AC- | 5/16-24 | .3125 | 2-1/4 | 1-3/4 | 2-1/8 | 6,900 |

| AN676AC- | 3/8-24 | .375 | 2-3/8 | 1-7/8 | 2-1/4 | 10,000 |

| AN677AC- | 7/16-20 | .4375 | 2-5/8 | 2-1/8 | 2-1/2 | 13,700 |

| AN678AC- | 1/2-20 | .500 | 2-7/8 | 2-3/8 | 2-7/8 | 18,500 |

| AN679AC- | 9/16-18 | .5625 | 3-1/8 | 2-5/8 | 3-1/4 | 24,000 |

| AN680AC- | 5/8-18 | .625 | 3-3/8 | 2-7/8 | 3-1/2 | 29,500 |

| AN682AC- | 3/4-16 | .750 | 3-3/4 | 3-1/4 | 4-3/8 | 42,000 |

| ** See Notes (above) | ||||||

| ROUND TIE RODS | ||||||

|

||||||

| AN NUMBER | Size & Thread |

Diameter (Inches) |

Thread Length (Inches) | K | Min. Strength (lbs.) |

|

| RH | LH | |||||

| AN701AC- | 6-40 | .138 | 1-3/4 | 1-1/4 | 1-1/4 | 1,000 |

| AN703AC- | 10-32 | .190 | 1-7/8 | 1-3/8 | 1-1/2 | 2,100 |

| AN704AC- | 1/4-28 | .250 | 2-1/8 | 1-5/8 | 1-7/8 | 3,400 |

| AN705AC- | 5/16-24 | .3125 | 2-1/4 | 1-3/4 | 2-1/8 | 6,100 |

| AN706AC- | 3/8-24 | .375 | 2-3/8 | 1-7/8 | 2-1/4 | 8,000 |

| AN707AC- | 7/16-20 | .4375 | 2-5/8 | 2-1/8 | 2-1/2 | 11,500 |

| AN708AC- | 1/2-20 | .500 | 2-7/8 | 2-3/8 | 2-7/8 | 15,500 |

| ** See Notes (above) | ||||||

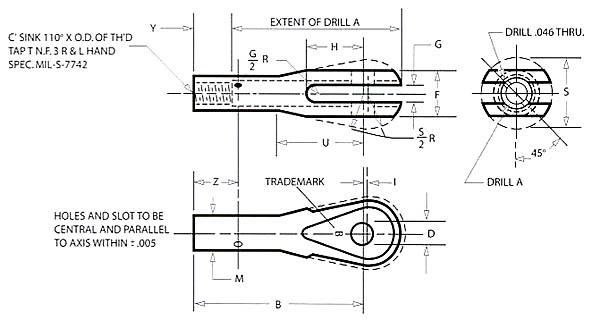

| TERMINALS, THREADED CLEVIS TYPE | ||||||||||||||

|

||||||||||||||

| AN665 TERMINALS | ||||||||||||||

| Dash No. |

Rated Tie Rod Strength Min. (lbs.) |

Tap T |

Drill A |

B ±.015 |

D Dia. +.003 -.000 |

F +.010 -.000 |

G +.010 -.000 |

H | I +.010 -.000 |

M Dia. +.010 -.000 |

S Dia. |

U | Y ±.047 |

Z |

| 10L 10R |

1,200 | 6-40 | .147 | 1.313 | .190 ** | .250 | .109 | .375 | .031 | .250 | .375 | .625 | .250 | .313 |

| 21L 21R |

2,400 | 10-32 | .199 | 1.531 | .190 ** | .313 | .150 | .469 | .031 | .281 | .500 | .719 | .313 | .375 |

| 34L 34R |

4,200 | 1/4-28 | .261 | 1.813 | .250 | .438 | .203 | .625 | .047 | .375 | .625 | .875 | .438 | .500 |

| 46L 46R |

(a) 4,600 | 5/16-24 | .323 | 1.875 | .313 | .500 | .203 | .656 | .047 | .438 | .688 | .938 | .563 | .625 |

| 61L 61R |

6,900 | 5/16-24 | .323 | 2.000 | .375 | .563 | .203 | .844 | .063 | .453 | .750 | 1.000 | .563 | .625 |

| 80L 80R |

10,000 | 3/8-24 | .386 | 2.250 | .375 | .563 | .266 | .875 | .063 | .547 | .875 | 1.125 | .688 | .750 |

| 80LA 80RA |

10,000 | 3/8-24 | .386 | 2.250 | .375 | .625 | .266 | .875 | .063 | .547 | .875 | 1.125 | .688 | .750 |

| 115L 115R |

13,700 | 7/16-20 | .453 | 2.500 | .438 | .719 | .344 | 1.000 | .078 | .625 | 1.063 | 1.250 | .750 | .813 |

| 155L 155R |

18,500 | 1/2-20 | .516 | 2.813 | .500 | .813 | .406 | 1.188 | .078 | .703 | 1.188 | 1.438 | .875 | .938 |

| 202L 202R |

24,000 | 9/16-18 | .578 | 3.125 | .563 | .922 | .453 | 1.375 | .094 | .796 | 1.375 | 1.625 | 1.000 | 1.063 |

| 247L 247R |

29,500 | 5/8-18 | .640 | 3.375 | .625 | 1.032 | .516 | 1.500 | .094 | .875 | 1.500 | 1.750 | 1.125 | 1.188 |

| 430L 430R |

42,000 | 3/4-16 | .766 | 4.125 | .750 | 1.250 | .656 | 1.938 | .109 | 1.063 | 1.813 | 2.250 | 1.375 | 1.438 |

| NOTES: ** Tolerances: +.002 -.000 for .190 dia. only (a) Special for AN675 rod with 4600 lb. rating. |

||||||||||||||

- Material is 6S80 Stainless Steel, satin finish. (MIL-T-5683)

- Tolerances:

Fractions ± 1/64

Decimals ± .010

Angles ± 1/2 degree - When specifying use dash numbers:

Example:

AN665-61L defines a 5/16-24 terminal, 6900 lb. rating, L.H. thread.